Laser Cutting & Engraving Wood | Tips and Tricks

Last Updated - October 2024

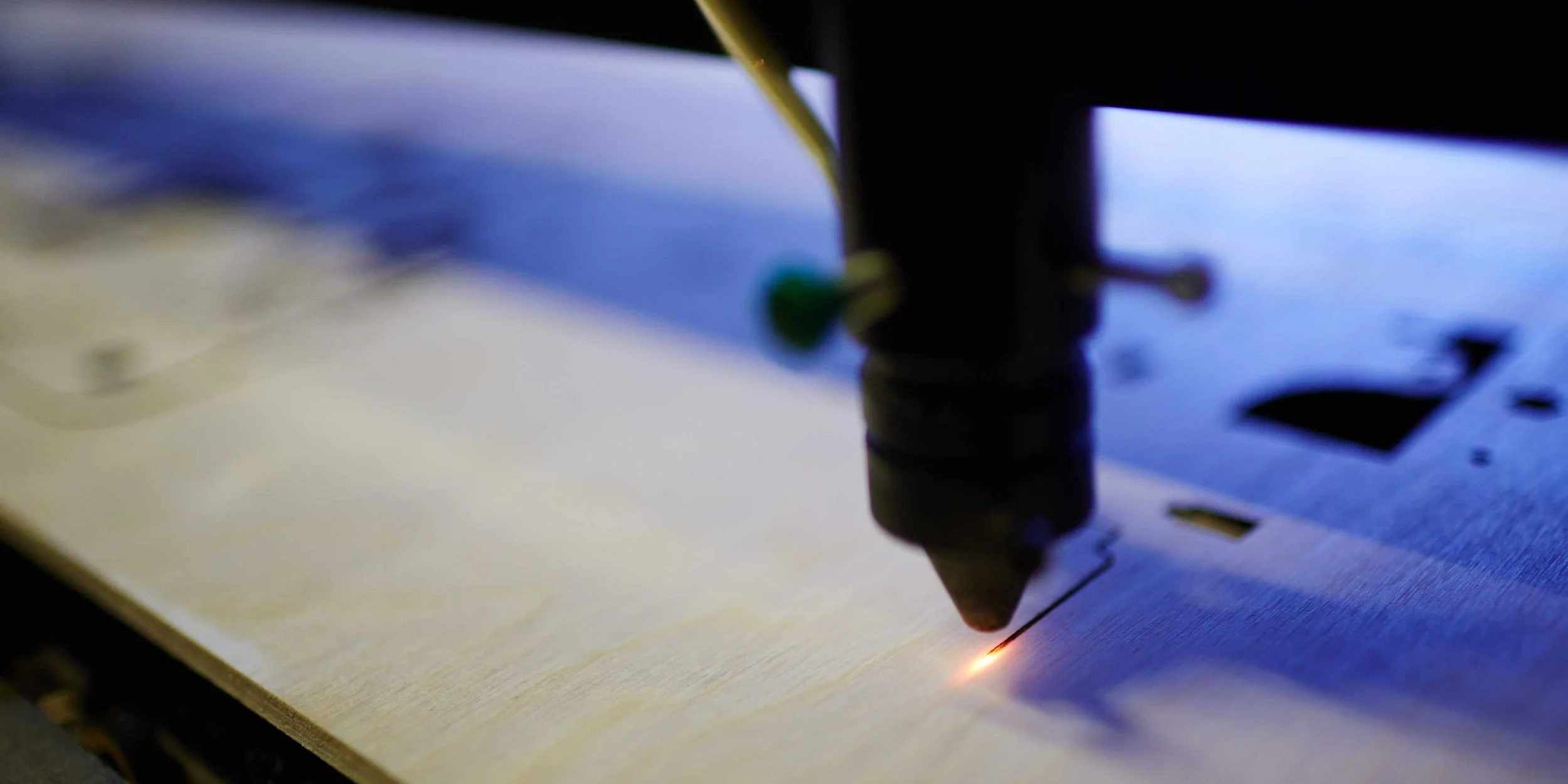

Whether you're a seasoned professional or just starting your journey into the world of CO2 laser technology, within this guide, we've shared a range of invaluable wood engraving tips and tricks to help you achieve stunning results, ranging from exploring the best wood types to minimising scorching.

Additionally, we welcome your insights! If you have any personal tips for laser engraving or cutting wood, please comment below.

Two Key Factors to Consider

Wood Resin: What You Need to Know

When choosing a suitable wood type for your laser cutting or engraving project, it's essential to take into consideration wood types with high levels of resin.

Wood resin, or sap, is a natural substance found in both the sapwood and heartwood of trees. It seals off wounds and shields trees from pests, diseases, and environmental hazards. The quantity of resin a tree produces varies based on factors like species, age, and environmental conditions.

When wood with high resin content is laser engraved or cut, the heat generated by the laser beam can cause the resin to melt and spread across the surface of the wood, creating a dark, unsightly discolouration.

The Secret to Perfect Wood Engraving: Avoiding Streaks

Wood streaks refer to the natural discolourations or irregularities in the wood grain that occur due to the environmental conditions in which a tree is grown. These streaks can vary in colour, density, and pattern. Sadly, these streaks can vary in thickness, leading to inconsistent results when laser engraving or cutting wood. Therefore, we advise choosing wood types with minimal streaking to ensure consistent results.

Best Wood Types For Laser Cutting and Engraving

When it comes to laser engraving or cutting wood, its natural inconsistencies can produce unpredictable results. We recommend choosing uniform wood types with minimal streaking and resin content, such as maple, cherry, and alder wood.

Maple Wood

Maple wood, prized for its light colour, is favoured by furniture makers. Its tight grain pattern ensures consistent results in laser cutting and engraving, ideal for intricate designs and text. Additionally, it has some of the lowest sap levels when compared to other wood species.

Cherry Wood

Cherry wood is a popular wood type used in producing high-quality furniture, such as chairs, tables, cabinets, and dressers. Cherry wood is a popular choice for laser cutting and engraving due to its tight, uniform grain pattern, relatively low resin content, and beautiful reddish-brown colour. Cherry wood is also known for its durability and resistance to wear and tear, making it an ideal choice for outdoor signs or plaques.

Alder Wood

Alder wood is a popular choice in architecture and interior design due to its ability to absorb laser energy evenly, minimising scorch marks. It's also durable and resistant to warping.

Additional wood types ideal for use with CO2 laser technology include Balsa, Boxwood, Bamboo, Oak and Cedar.

Wood Engraving Tips

Explore a range of wood engraving tips to achieve stunning results when using CO2 laser technology.

Remember, we welcome your insight! If you have any personal tips for laser engraving or cutting wood, please comment below.

Laser Cutting Plywood

We recommend using LaserPly, which is produced specifically for CO2 laser technology.

Plywood consists of multiple thin layers of wood glued together in an alternating grain pattern and compressed, which provides both strength and stability. You should avoid sourcing low-quality plywood that may contain voids or knots that can cause the laser to cut unevenly or cause unwanted flare-ups or scorchings.

High-quality Baltic birch plywood is a popular choice due to its smooth, uniform surface and attractive light colour. Birch plywood typically has a low resin content, which makes it easy to cut and engrave with a CO2 laser.

How Do You Engrave Wood without Burning It?

One of the downsides of laser cutting or engraving wood is the unsightly charred effect left around the processing path due to the high temperatures emitted by the laser beam. You can minimise this scorching effect by testing the different laser parameters, engraving in layers, applying masking tape, dampening the wood and turning your extraction system to the max.

Below, we will explore each of these points in depth.

Test, Test and Test Again.

Wood is a natural material. All wood types, even those of the same species, have different densities, which can result in inconsistent results when laser cutting or engraving wood. We recommend carrying out a test run to determine the optimal power settings. Start with a lower power setting and gradually increase until you achieve the desired effect.

Engrave Wood in Layers

Engraving your design in layers instead of a single pass will produce a crisper, cleaner finish. Additionally, engraving in layers will reduce the amount of heat transferred from the laser beam to the wood during the engraving process, which will minimise the risk of scorching.

Apply Masking Tape

Apply masking tape to the wood surface before engraving. The tape will act as a protective layer that absorbs some of the energy from the laser beam, reducing the risk of burning or scorching the wood. Additionally, any debris or dust that collects on the tape can be easily removed by peeling off the tape, leaving the wood surface clean and free of any debris.

Unleash the Full Power of Your Extraction System

Crank it up! When processing wood on a laser machine, you should have your extraction system turned up to the max to help remove the smoke, fumes, and dust generated during the laser cutting or engraving process.

Dampen the Wood

To minimise scorching, lightly dampen the wood's surface using a spray bottle or damp rag. Avoid soaking the wood, and remember to apply water outside of the laser cutter.

How Do You Clean Laser Engraved Wood?

There are a range of techniques you can use to clean laser engraved wood to remove the unsightly charing left behind after the cutting or engraving process including:

Sanding down the engraved area

Use white wine vinegar

Hot soapy water

Below, we will explore each of these techniques for cleaning laser engraved wood in more depth.

Sanding Down Engraved Wood

Sanding down laser engraved or cut wood is a simple process that can help smooth out any rough or uneven areas, remove any unsightly charring and enhance the overall appearance of the engraving.

Wrap the sanding paper around a block of wood. The block of wood provides a sturdy grip and control while sanding, allowing you to apply consistent pressure and maintain a steady sanding motion.

When sanding the wood, always sand with the grain of the wood rather than against it. Additionally, the sandpaper you choose will depend on the wood type and the engraving depth. Fine-grit sandpaper, such as 220-grit or higher, is often a good choice for smoothing out the surface of the wood without damaging the engraving.

After sanding, wipe the surface of the wood with a clean, dry cloth to remove any dust or debris and repeat if necessary.

White Wine Vinegar

Using white wine vinegar is an excellent method for cleaning laser engraving wood because it is a mild acid that can effectively break down dirt and grime without causing damage to the wood or the engraving.

Dilute white wine vinegar with water in a 1:1 ratio. Dip a paper towel or a soft cloth into the solution and use it to wipe the residue from the wood. Repeat until you're happy with the outcome.

Using Soapy Cold Water

Using soapy water is a simple and effective way to clean laser engraved wood. Here are some steps to follow when using soapy water:

Mix the solution: Mix a few drops of mild dish soap in a bowl of lukewarm water to create a soapy solution.

Dip a soft cloth: Dip a soft cloth into the soapy solution and wring it out to remove excess water.

Wipe the surface: Gently wipe the surface of the laser-engraved wood with the cloth, applying light pressure as needed to remove any dirt or grime.

Dry thoroughly: After cleaning the wood, dry it thoroughly with a clean, dry cloth to prevent any water damage or warping.

By following these steps and using a gentle soap and a soft cloth, you can effectively clean any unsightly charring on your wood.

How to Choose a Wood Engraving Machine?

We hope you've found our wood engraving tips and exploration of the steps you can take to minimise the charred, scorching effect caused during the laser cutting and engraving process, and additionally, how to clean laser engraved wood to create a crisp, clean finish.

For those of you looking to purchase a wood engraving machine, you'll want to take into consideration:

Your budget

The power of the laser

The size and weight of the stones you're looking to engrave

What training is provided?

Safety features

Maintenance, repairs and replacement parts.

We have a brilliant guide to buying the best laser machine for your needs, where we explore each of these points in more depth.

Alternatively, when in doubt, speak to the experts. At Focused Laser Systems, we are the UK's leading laser cutter supplier and repair specialists, where we focus on affordability and reliability.

Our laser machines have been designed with decades of industry knowledge at their core, using only the highest quality components.

From desktop laser cutters to large format laser machines, our laser systems are available in an array of bed sizes and power levels, ideally suited for various applications and industries, ranging from creatives and hobbyists to schools, universities, small businesses and manufacturing.