Your One-Stop Destination in the UK for CO2 Laser Cutters, Engravers, Servicing, Installations, Repairs & Spare Parts.

Focused Laser Systems

Trusted By

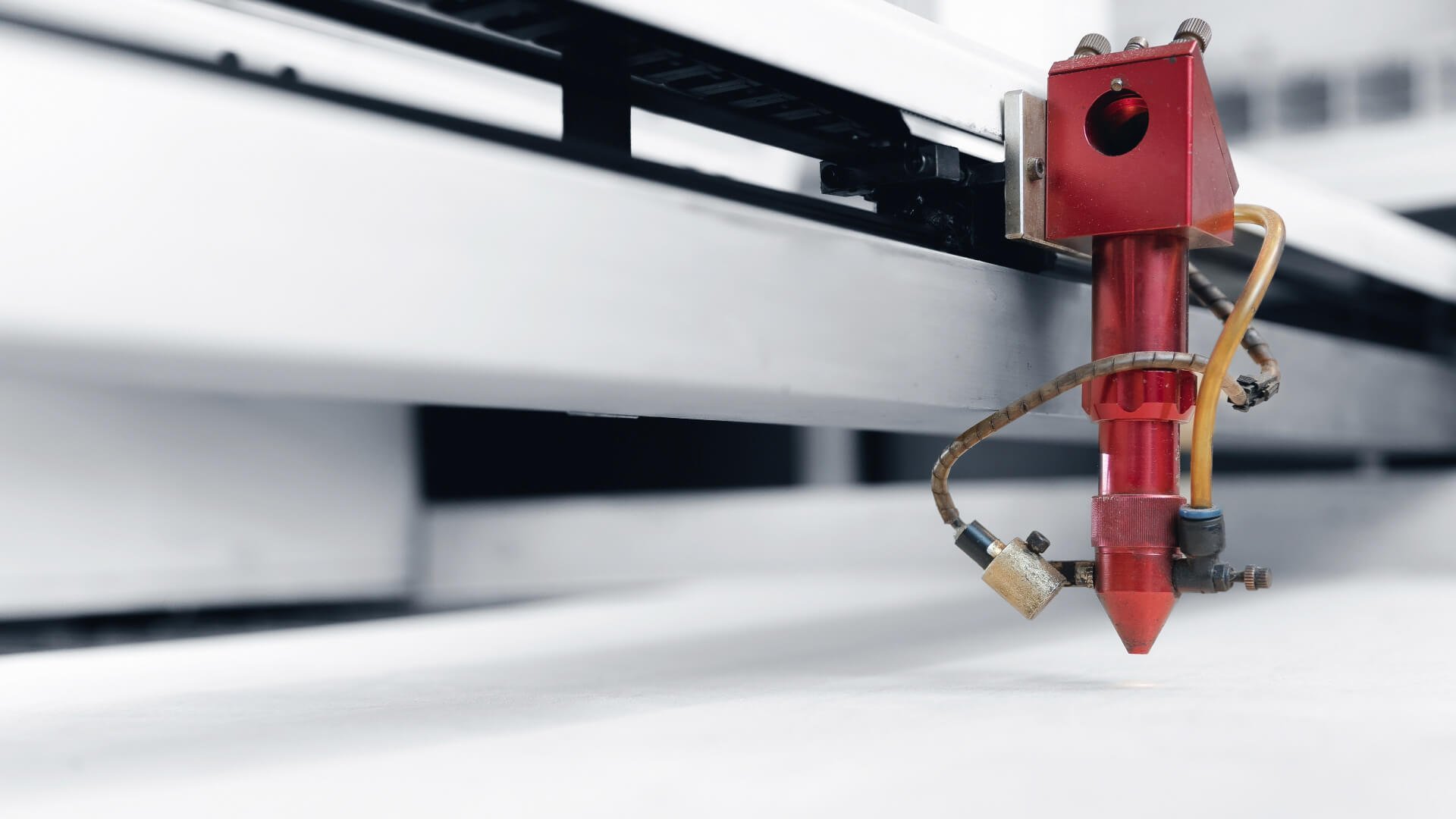

Laser Machines Engineered for Longevity

Welcome to Focused Laser Systems! Based in Devon, we are one of the UK's leading CO2 laser machine suppliers committed to affordability and reliability, and the leading experts in co2 laser machine repairs & servicing.

Our laser cutters have been designed with decades of industry knowledge at their core, using only the highest quality components.

Available in an array of bed sizes and power levels, our laser systems are ideally suited for various applications and industries, ranging from creatives and hobbyists to schools, universities, small businesses and manufacturing.

We also provide an all-encompassing range of services to streamline your journey in the world of laser technology, from laser cutter repairs + servicing, to training, installation, machine relocations and spare parts. We've got you covered.

Our CO2 Laser Cutters

Designed, built, and thoroughly tested in the UK, our Class 1 safety CO2 laser cutting machines are provided with installation, training, lifetime technical support and an industry-leading 2-year warranty to provide peace of mind.

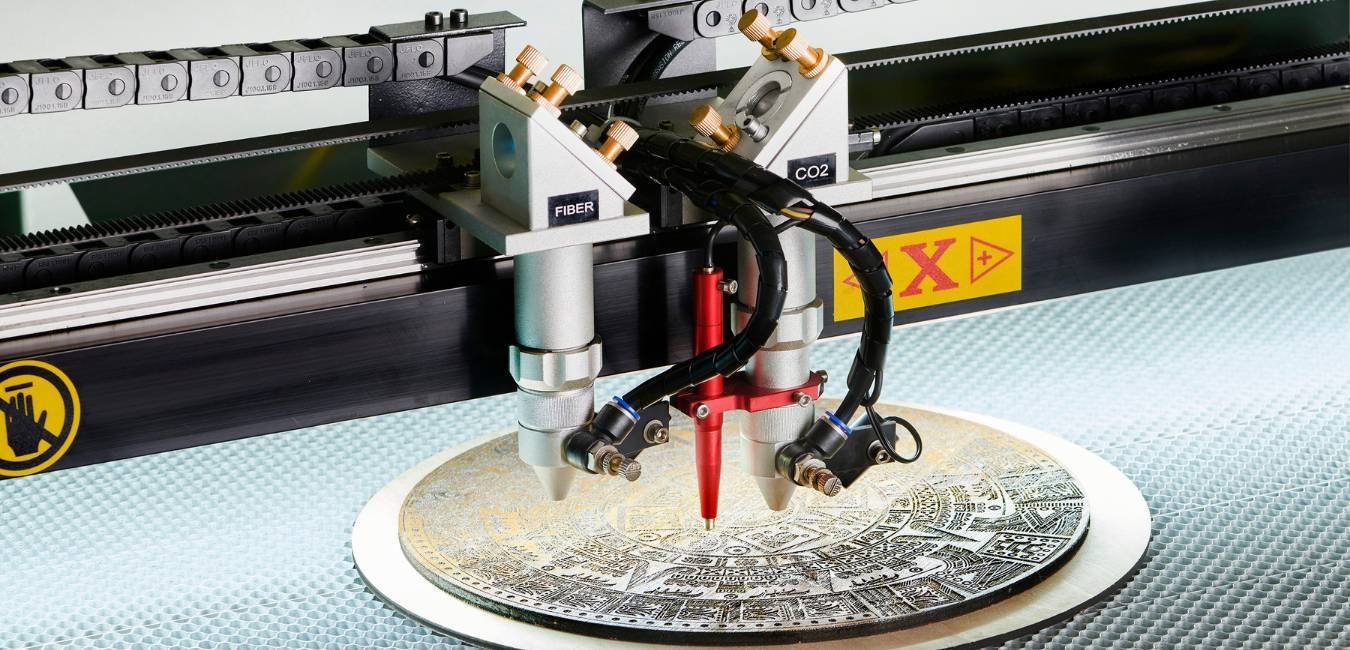

Dual Source Metal Engraving Machines

Choose a laser engraver that combines a fiber and CO2 laser tube in one system. This allows you to engrave a wide range of metals while still being able to cut and engrave non-metallic materials like acrylic, wood, and glass.

Refurbished Laser Machines

Are you looking for an affordable laser cutter? Vigorously tested and refurbished by our laser technicians, all second-hand laser systems come with a one-year warranty and our lifetime technical support services.

Laser Cutter Repairs

Providing affordable laser machine repairs, servicing, and upgrades for all makes and models of CO2 lasers, from desktops to industrial-sized laser machines.

Whether you're a beginner or a seasoned pro, our laser and software training will help you unlock your creative potential. We offer personalised training for various laser cutter brands and design software, including Adobe Illustrator, CorelDRAW, Lightburn, and RDWorks.

Laser Machine Training

Our Co2 Lasers

Buy a new or refurbished Vision laser machine and enjoy lifetime technical support. We also offer maintenance, call-outs, and support for all CO2 laser machines, regardless of brand.

Desktop Laser Cutter

With a 300mm x 400mm processing area, our desktop laser engraver will transform your desk into a workshop. It is ideally suited for crafts, small businesses, and education.

Engraver for Hobbyists

Our most compact and affordable CO2 laser cutter. Our Vision 4060, with its generous 400mm x 600mm processing area, is the ideal laser cutter for hobbyists due to its intuitive, easy-to-learn software.

Most Popular CO2 Laser

Why? Because nothing else cuts through the competition quite like our CO2 laser! Furthermore, the 600mm x 900mm processing area accommodates a wide range of project sizes, making it an ideal choice across various applications and industries.

The Best Laser Cutter for Small Businesses

The Vision 1290 is our most popular for small businesses, with its 1200mm x 900mm processing area, paired with the added option to upgrade your laser tube for additional power and speed when laser cutting or engraving.

Take your operations to the next level with our large-format laser cutting machines. With their expansive 1400mm x 900mm processing area and 80w laser tube as standard, and with the option to upgrade to 150w you'll be able to handle large-scale projects effortlessly.

Large Laser Cutter

Industrial Laser Cutter

Open up new opportunities for growth and innovation with our industrial laser cutting machine, which boasts a whopping 1600mm x 1000mm processing area, and let's not forget about the 2-year warranty and lifetime technical support.

Why Choose Focused Laser Systems?

When you invest in a laser system, you deserve a company with tech support on speed dial and all the knowledge to help — because laser precision shouldn't leave you hanging! That's why we offer lifetime technical support with any machine sale. Additionally, we provide a range of services and ongoing support so you can concentrate on getting the most out of your laser machine.

Materials You Can Cut & Engrave on Our CO2 Lasers

Our Co2 laser cutters can cut and engrave a wide range of materials. Additionally, applying a metal marking spray allows your laser machine to create high-contrast designs on most common metals, including aluminium, stainless steel, brass, nickel plating, and more.

Get in Touch

Interest in one of our new or refurbished laser systems? Or is your laser machine in need of some TLC? Our technicians and sales team are here to answer any queries you may have. Alternatively, call us on 01271 626 406.

Frequestions Asked Questions

Buying a CO2 laser cutter for the first time can be a daunting process, often leaving you with numerous questions. Below, we've addressed some of the common questions we receive from our customers.

-

Based in Devon in the South West, we've provided our laser machines and all-encompassing range of services to individuals, companies, and education facilities throughout England, Wales, Scotland, and Northern Ireland over the years.

Our engineers are constantly zipping up and down the country. We strive to provide the quickest call-outs in the industry paired with maximum flexibility.

-

The primary distinctions between CO2 and fiber laser cutters lie in their applications and technology. CO2 laser cutters employ a gas mixture to generate a laser ideal for cutting non-metal materials and engraving.

In contrast, fiber laser cutters utilise a solid-state diode and fiber optic to achieve more efficient metal cutting. This efficiency is due to their shorter wavelength, which metals absorb more effectively.

-

Here at Focused Laser Systems we work with Kennet Equipment Finance to provide great finance options for all of our new and refurbished laser systems. These options are perfect for spreading the cost of your laser system over a number of years while allowing your business to reap the benefits of a co2 laser machine.

Kennet Equipment Leasing is one of the UK’s leading providers of business equipment finance and asset leasing, enabling customers to invest in the very latest business equipment without drawing on critical working capital.

If you’d like more information on how Kennet Equipment Leasing can give your business the power to grow please call Mark Suckley on 01675 469215 or select an option below.

-

You'll first want to consider the materials you're looking to process. If you're interested in laser cutting and engraving non-metallic materials like glass, acrylic, wood, and stone, a Co2 laser is an excellent choice.

Alternatively, we recommend our dual-source laser machines for those seeking the versatility to process both metallic and non-metallic materials.

You should also consider the size and shape of the materials you plan to process to ensure that your laser cutter's bed size is large enough to fit the largest piece you intend to work with.

Additionally, you'll want to consider the power level of your laser tube (measured in watts), with higher-wattage tubes having the ability to cut or engrave thicker materials faster than lower-wattage tubes.

When choosing a suitable laser cutting machine, various factors should guide your decision, all of which we've explored in our comprehensive laser cutter buying guide. Or why not give us a call?

-

A CO2 laser is a versatile tool capable of processing a wide range of non-metallic materials ranging from glass to acrylic, wood, stone, fabrics, leather, paper, and cardboard, to name a few.

Check out our full comprehensive list of materials our CO2 laser machines can process.

-

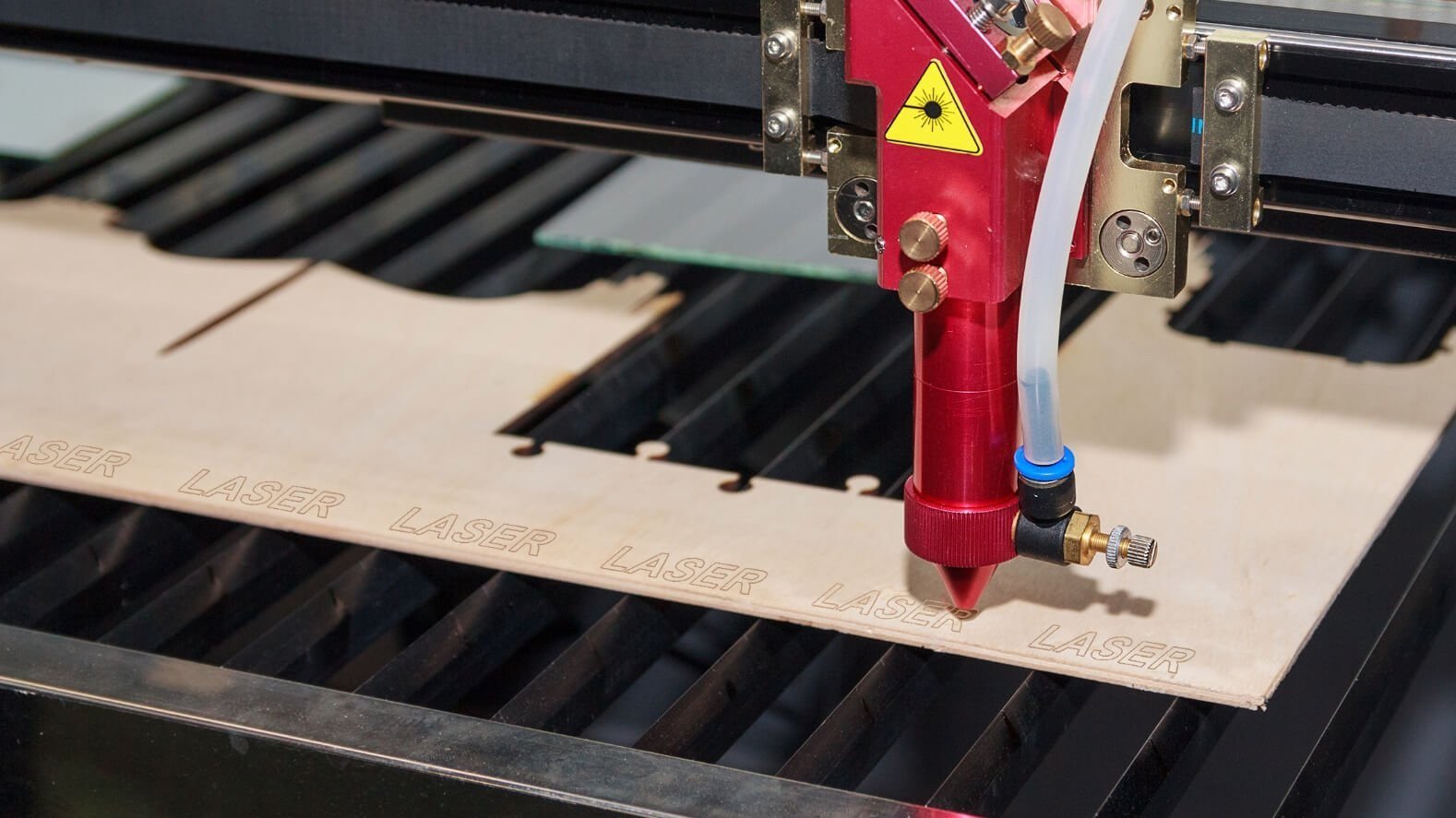

A laser cutter works by creating a high-powered laser beam in a glass laser tube that contains a mixture of specific gases including nitrogen and carbon dioxide.

The laser beam is then projected through a lens in the end of the laser tube, and is then reflected off a series of mirrors, and then refined through a focal lens onto the surface of a material.

The laser beam moves along a programmed path that heats the material's surface until it reaches its melting or evaporation point, creating a narrow and precise cut or engraving into the material.

The entire process is controlled by computer software, which allows for the precise cutting of intricate designs. The laser beam can be adjusted to different power intensities, speeds, and settings depending on the material being cut or engraved, allowing for flexibility when processing a range of materials.

-

Initially limited to industrial manufacturing applications, technological advances have reduced the production cost of these versatile laser systems over the decades, making them increasingly popular amongst universities, schools, small businesses, creatives and hobbyists due to their ability to cut and engrave intricate designs out of a range of materials at incredible speed that be near on impossible to achieve manually.

-

The lifespan of a laser tube varies depending on the power rating, usage, and maintenance. However, on average, a CO2 laser tube can last between 2 to 5 years.

Laser tubes with proper care and moderate use often reach the upper end of this scale, ensuring longevity and consistent performance. Regular maintenance, including cleaning and alignment, can significantly extend a laser tube's lifespan.

Check out our blog, where we have a range of handy tips on how to prolong the life of your laser tube.

-

You'll first want to consider the materials you're looking to process. If you're interested in laser cutting and engraving non-metallic materials like glass, acrylic, wood, and stone, a Co2 laser is an excellent choice.

Alternatively, we recommend our dual-source laser machines for those seeking the versatility to process both metallic and non-metallic materials.

You should also consider the size and shape of the materials you plan to process to ensure that your laser cutter's bed size is large enough to fit the largest piece you intend to work with.

Additionally, you'll want to consider the power level of your laser tube (measured in watts), with higher-wattage tubes having the ability to cut or engrave thicker materials faster than lower-wattage tubes.

When choosing a suitable laser cutting machine, various factors should guide your decision, all of which we've explored in our comprehensive laser cutter buying guide. Or why not give us a call?

Featured Posts.

Tips for maximising your laser machine: achieve precise engraving, clean cutting edges, reduce processing time and more.

Don't let unexpected downtime derail your projects. Learn about common CO2 laser repairs, from laser tube replacement to power supply issues, and keep your machine operating at peak performance.